Customer Success Story: End-to-End Door-to-Door Logistics from China to Mexico

When I first sat down with Lisa from Sunny Worldwide Logistics in April 2025, I didn't expect to find a partner who would treat my cargo like their own responsibility. I'm Javier Rascon, and I represent a growing furniture and home supply distribution business in Ensenada, Mexico. We had just landed a major contract to supply high-end furniture across Mexico, and we needed someone in China who could handle the entire supply chain—not just book containers, but truly manage every detail from factory floor to my warehouse door.

The challenge was enormous: 26 x 40HQ containers from multiple Guangzhou manufacturing partners, each with different production schedules. We needed guaranteed quality, transparent monitoring, reliable quality inspection in China, and a logistics provider who could coordinate across time zones without communication delays. Most importantly, we needed someone who understood that in international freight forwarding, one mistake could cost us thousands in penalties and lost business.

That's when Sunny Worldwide Logistics proved they weren't just another door-to-door shipping service. They were partners who would actually invest in understanding my business.

When Lisa arrived at our factories in April, I'll be honest—I wasn't expecting much different from what we'd experienced with other freight forwarders. They usually just show up to book containers. Lisa didn't. She spent three full days walking through every production line, asking detailed questions about material sourcing, production schedules, packaging specifications, and Mexico customs requirements.

What impressed me most was that she treated factory conditions seriously. Even though our manufacturing partners were operating in tight spaces with limited equipment, Lisa didn't use that as an excuse to skip verification steps. Instead, she documented everything systematically—supplier certifications, production timelines, packaging materials, load capacity testing, and export documentation requirements. She asked if we had proper factory audit support processes in place, and when we said no, she recommended an improvement plan.

That first factory inspection told me everything I needed to know: Sunny Worldwide Logistics wasn't interested in just moving boxes. They wanted to understand my business, verify quality upstream, and prevent problems before they became expensive nightmares. This is what real international logistics partnerships look like.

Lesson learned: The cheapest logistics provider is often the most expensive one. Professional supply chain management starts at the factory gate, not the port gate.

By August, production was ramping up across all our manufacturing partners. That's when Sunny arranged three separate on-site quality inspections on the 7th, 12th, and 19th of the month. This isn't something most freight forwarders do—most just pick up containers without verification. But Sunny's Meiyang QC team—Sky, Macro, and Spring—showed up with professional inspection protocols and real commitment.

Here's what blew me away: they live-streamed factory walkthroughs. Not pre-recorded videos, but actual real-time streams showing production quality, packaging integrity, and load procedures. Within 24 hours of each inspection, I received a detailed English QC report with photos, measurements, and specific observations. This transparency was exactly what I needed—I could show my Mexican customers that their furniture was being monitored by professional third parties before it even left China.

The reports weren't just inspection documentation—they became my factories' improvement guides. Sunny's team identified specific packaging issues, suggested better stacking methods, and recommended protective materials that would reduce damage risk during ocean transit. One factory manager told me: "Sunny's QC report was better than most audits we've paid for." They weren't criticizing for criticism's sake; they were providing constructive feedback that actually improved our production process.

Real-world impact: Because of these QC inspections, we caught and corrected 14 packaging issues before shipping. That's 14 potential damage claims prevented. The cost of quality inspection was repaid 10 times over by avoiding cargo damage during transit.

By late August, all production lines were finishing simultaneously. That's when Sophia from Sunny's operations team took over scheduling. The task was complex: allocate 26 high-cube containers (40HQ) across multiple vessel schedules bound for Ensenada Port, while ensuring that shipment timing matched my warehouse capacity and installation schedule in Mexico.

Most logistics providers would just book space and send containers as they're ready. Sophia did something different. She contacted me specifically about my warehouse receiving capacity. "If we send all 26 containers arriving within the same week, can your warehouse handle the unloading, sorting, and storage?" That single question prevented a major operational disaster. We coordinated a phased delivery schedule that matched my warehouse's receiving capacity, our assembly team's workflow, and my customer delivery commitments.

Sunny's team leveraged their long-term partnerships with CMA CGM to secure premium space for all 26 containers, working within their existing freight agreements to provide competitive rates. They used their private warehouse at Yantian Port for consolidation and pre-shipment inspection—an extra step that most forwarders skip. Before each container left the warehouse, Sunny's team verified load accuracy against my original purchase orders and took photos for my records.

Why this matters: Coordinating 26 containers isn't just about logistics arithmetic. It's about understanding your customer's entire operation and making shipping decisions that support their business goals, not just moving cargo efficiently.

Once containers departed from Yantian in September and October, I expected the usual situation: silence until containers arrived in Mexico. Instead, Sunny's tracking team provided near-daily updates through their integrated digital platform. I received real-time vessel tracking, ETA updates, and customs clearance progress. For the first time in my shipping experience, I actually knew where my cargo was and when it would arrive.

The thing that impressed me most was that Sunny proactively managed Mexico customs documentation before containers even arrived. They worked with their partner agents (WCA and CIFA members) to prepare all required import documentation, certificates of origin, and customs declarations. When containers arrived at Ensenada Port, customs clearance took hours instead of days.

I'll be direct: I've used multiple freight forwarders over the years. Most of them treat Mexico as a distant port where things mysteriously happen and cargo somehow arrives. Sunny treated it as a critical point in the supply chain where coordination and professional relationships matter. They maintained constant communication with local partners, verified container condition at Ensenada, and coordinated inland delivery through their Mexico logistics network.

The reality check: Door-to-door shipping service means nothing if the "door" side isn't managed professionally. Sunny's Mexico partnerships were as important as their China operations.

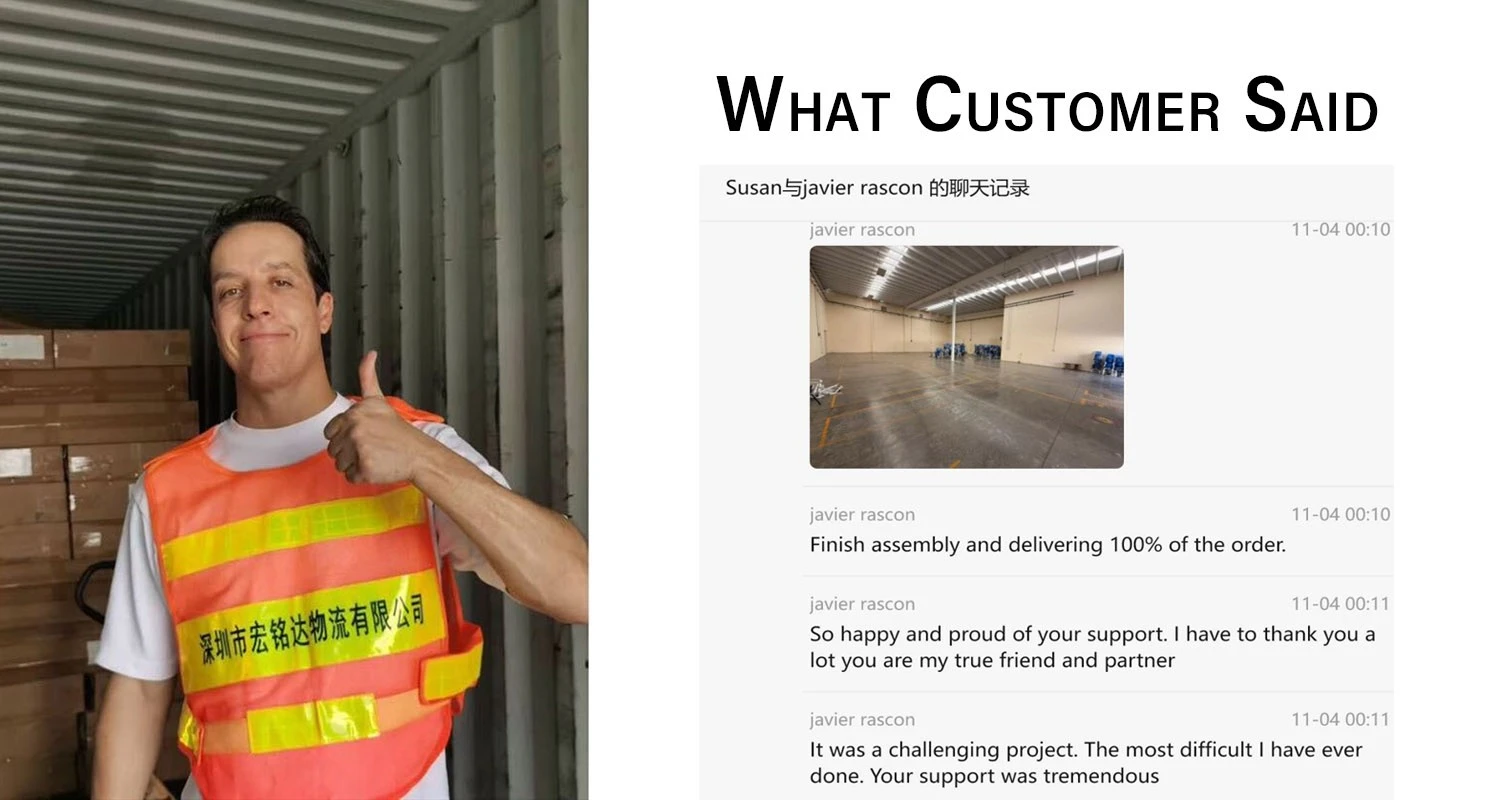

By late October, I watched as the final container arrived at my warehouse and was unloaded successfully. All 26 containers had made the journey from Guangzhou factories to Ensenada Port to my warehouse. My assembly team began unpacking, inspecting, and assembling the furniture. The quality was exactly as specified. Packaging had protected everything. Delivery timelines had matched our warehouse receiving schedule.

When I called Susan from Sunny's office to confirm successful delivery, the first thing she asked wasn't "Can we do this again?" It was "Did everything arrive as expected? Do you need anything else from us?" That simple question demonstrated something I've rarely experienced in logistics: genuine interest in customer success beyond the transaction.

The final score: 26 containers, zero damage, zero delays, zero customs issues, 100% customer satisfaction. Not because logistics is magical, but because every step was professionally managed and communicated.

Custom Feedback:

This project required coordination across multiple departments. From my perspective as the customer, here's who made the difference:

This wasn't a one-person performance. It was a department-by-department orchestration where each team understood their role in the larger customer success story.

Before working with Sunny Worldwide Logistics, I evaluated freight forwarders primarily on cost and reliability. After this Mexico project, I've expanded my criteria significantly. I now understand that international freight forwarding is fundamentally different from basic cargo transportation. It's about understanding your supply chain, proactively managing risk, maintaining transparent communication, and investing in technology and partnerships that create operational visibility.

I realized that cheap freight quotes often come with hidden costs: lack of visibility, poor quality management, customs delays, and ultimately, damaged cargo or missed deliveries. Sunny's approach costs more upfront but saves substantially by preventing problems rather than managing emergencies. Their QC process identified 14 potential issues before shipping. One damaged container would have cost more than all three inspections combined.

Most importantly, I realized that the best logistics partner treats my cargo like their own business is at stake. Because, honestly, both our businesses are connected. When Sunny's customers succeed, Sunny succeeds. That alignment creates incentives for honest communication, professional service, and continuous improvement—exactly what you need in a global supply chain.

If you're importing from China to Mexico, here's my honest feedback based on this 26-container experience:

After this project's success, I committed Sunny Worldwide Logistics as our exclusive China logistics partner for 2026 and beyond. Here's why:

First, they've proven they understand our business model. Sunny doesn't treat all shipments as commodities. They understand that furniture shipping from China to Mexico requires specific expertise—handling oversized products, managing warehouse timing, maintaining quality standards, and ensuring compliance with Mexican customs regulations. When I presented new sourcing opportunities for 2026, they immediately suggested improvements based on what they learned from this project.

Second, their technology platform integrates with our operations. We now get daily updates on production schedules, quality assessments, and shipment tracking through their system. This isn't complicated software—it's practical, user-friendly visibility that actually helps us run our business.

Third, and most importantly, we've built genuine trust. When Lisa visits our factories now, we discuss business opportunities, not just logistics. When Susan calls, it's to solve problems and explore improvements, not just process transactions. That relationship is exactly what I want in an international logistics partner.

I've been in import/export business for over a decade. I've worked with dozens of freight forwarders across different routes. This Mexico project with Sunny Worldwide Logistics stands out because it wasn't just transactional. Every decision—from factory inspection through final delivery—was made with my business success in mind.

The 26 containers arrived safely. My customers received exactly what they ordered. My installation schedule stayed on track. My business grew as planned. That's what I needed, and that's what Sunny delivered.

When I thanked Susan after the final delivery, she asked: "What can we do better next time?" That question—showing genuine interest in continuous improvement rather than just celebrating success—tells you everything about Sunny Worldwide Logistics' approach to customer partnerships.

It was a tough journey from Guangzhou factories to Mexico warehouses, but Sunny made it happen. Not just as a freight forwarder, but as a true partner. That's why they're not just our logistics provider anymore—they're an essential part of our supply chain success.