The Ultimate Guide to Warehouse Management: End-to-End Process from Receiving to Dispatch

Published on September 8, 2025

Introduction

In today's competitive supply chain landscape, effective warehouse management is crucial for business success. A well-organized warehouse services operation can significantly impact your bottom line, customer satisfaction, and overall operational efficiency. Understanding the complete warehouse process flow is essential for businesses looking to optimize their logistics operations.

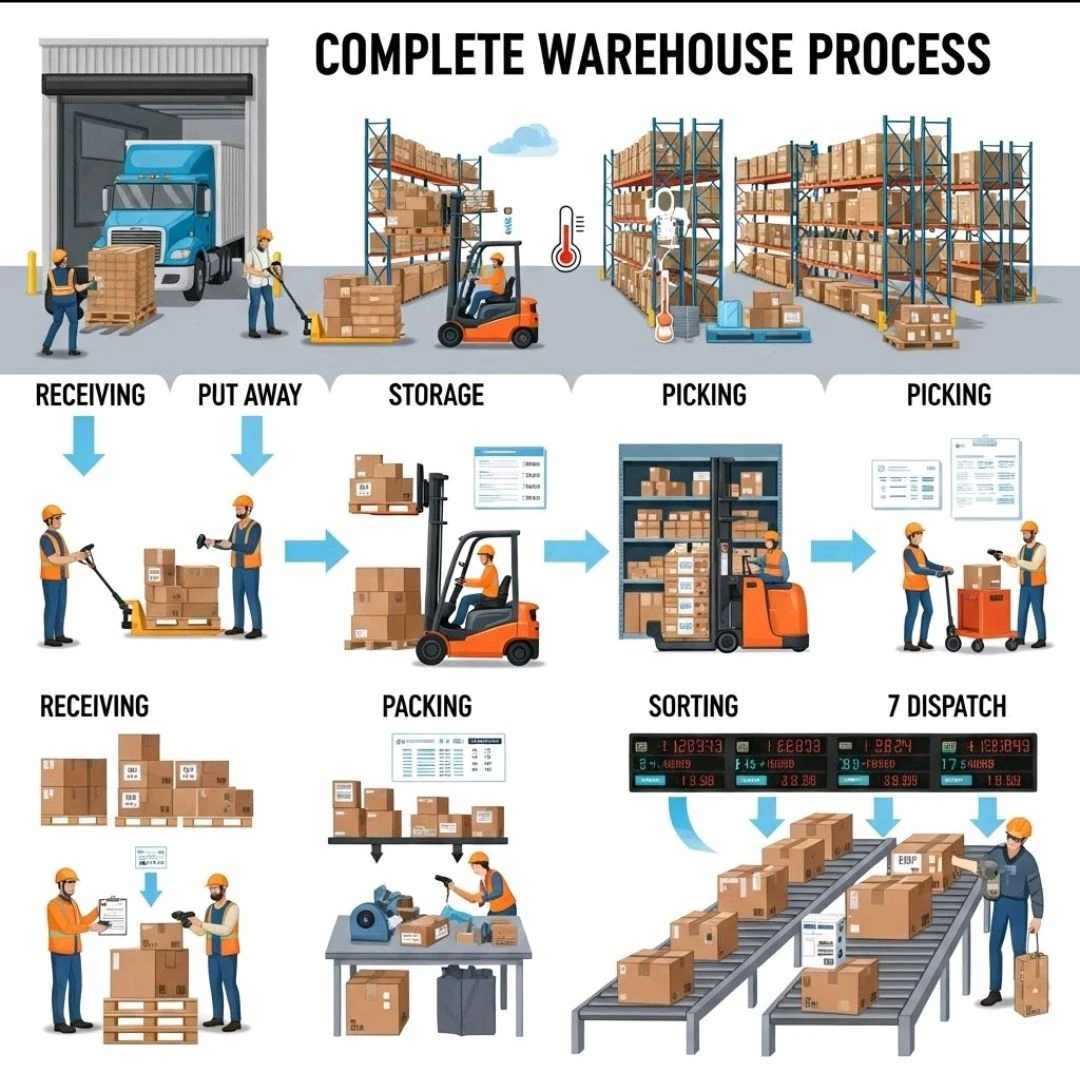

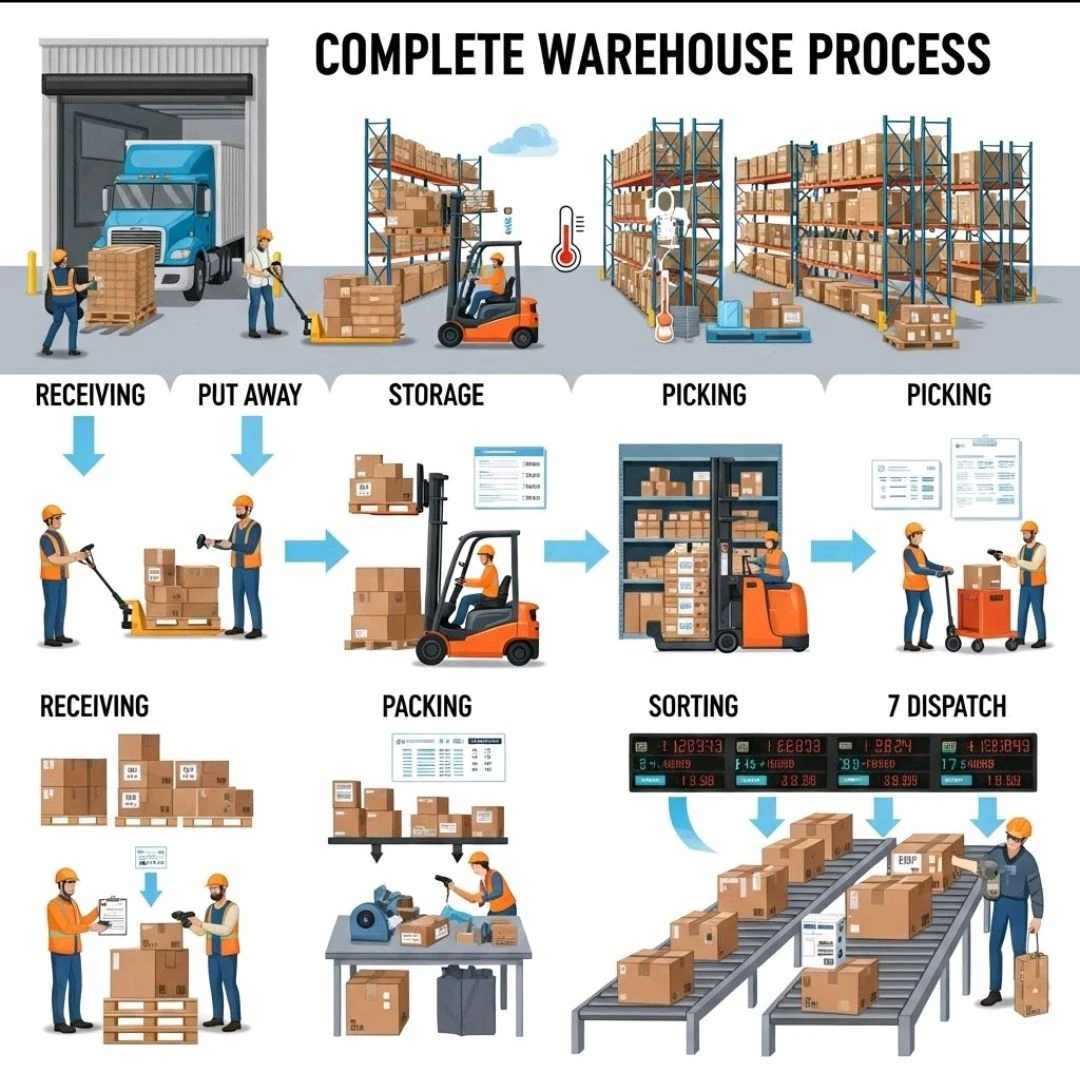

Understanding the Complete Warehouse Process

1. Receiving (Inbound Operations)

The warehouse journey begins with the receiving process, which sets the foundation for all subsequent operations:

- Goods Arrival: Merchandise arrives from suppliers and vendors

- Quality Inspection: Thorough checking for quantity accuracy, quality standards, and potential damages

- Documentation: Goods Receipt Note (GRN) creation for proper record-keeping

- Identification: Barcoding and labeling procedures to ensure traceability

Professional warehouse services ensure that this critical first step maintains accuracy rates above 99%.

2. Put-Away Operations

Strategic placement of inventory is crucial for operational efficiency:

- Location Assignment: Items stored in optimal locations (racks, shelves, bins, cold storage facilities)

- FIFO/FEFO Implementation: First-In-First-Out and First-Expired-First-Out systems

- System Updates: Real-time location tracking in warehouse management systems

3. Storage & Inventory Management

Effective inventory control is the heart of successful warehouse operations:

- Strategic Slotting: Fast-moving items placed in easily accessible locations

- Inventory Accuracy: Regular cycle counting and comprehensive stock audits

- Quality Control: Safety inspections and isolation of expired or damaged stock

- Space Optimization: Maximizing storage capacity while maintaining accessibility

4. Order Processing (Outbound Operations)

The order fulfillment process transforms customer demands into actionable tasks:

- Order Reception: Customer orders received through various channels

- Pick List Generation: Automated systems create optimized picking routes

- Strategy Implementation: Zone picking, batch picking, and FIFO/FEFO methodologies

5. Picking & Packing Operations

Accuracy in picking and packing directly impacts customer satisfaction:

- Item Retrieval: Systematic picking from designated storage locations

- Quality Assurance: Multiple quality checks throughout the process

- Packaging Standards: Safe and secure packaging with proper labels, barcodes, and shipping documentation

Our professional warehouse services maintain picking accuracy rates of 99.8% or higher.

6. Dispatch & Shipping

The final outbound step ensures timely delivery:

- Loading Operations: Efficient loading of goods into trucks and courier vehicles

- Documentation: Delivery challans and invoices properly attached

- System Updates: Real-time status updates as "Dispatched"

- Tracking Integration: Seamless integration with shipping tracking systems

7. Returns Management (Reverse Logistics)

Effective returns processing is crucial for maintaining inventory accuracy:

- Inspection Process: Thorough examination of returned items

- Inventory Restoration: Usable stock returned to active inventory

- Disposal Management: Non-usable items properly scrapped or claimed

8. Reporting & Documentation

Comprehensive reporting ensures continuous improvement:

- Daily Operations Reports: Inbound and outbound activity summaries

- Inventory Analytics: Real-time inventory balance and turnover reports

- Compliance Documentation: Safety and regulatory compliance reports

- Performance Metrics: Cost analysis and productivity measurements

The Complete Warehouse Process Flow

Receiving → Put-away → Storage → Order Processing → Picking → Packing → Dispatch → Returns → Reporting

Benefits of Professional Warehouse Management

A well-managed warehouse operation provides numerous advantages:

- Enhanced Efficiency: Streamlined processes reduce operational costs

- Improved Accuracy: Advanced systems minimize errors and discrepancies

- Customer Satisfaction: Faster processing and accurate deliveries

- Scalability: Flexible operations that grow with your business needs

- Cost Optimization: Reduced labor costs and improved space utilization

Conclusion

Effective warehouse management is not just about storing goods—it's about creating a strategic advantage in your supply chain. By implementing these comprehensive processes, businesses can achieve operational excellence and drive sustainable growth.

Professional warehouse services that follow these established processes become the heartbeat of successful supply chain operations, ensuring efficiency, accuracy, and customer satisfaction at every step.

Looking for professional warehouse management solutions? Contact us today to learn how our expert team can optimize your warehouse operations and drive business success.