Tel:18576695636

Facebook:https://www.facebook.com/profile.php?id=61551131221180

Contact Person:Anne

PDF Show:PDF

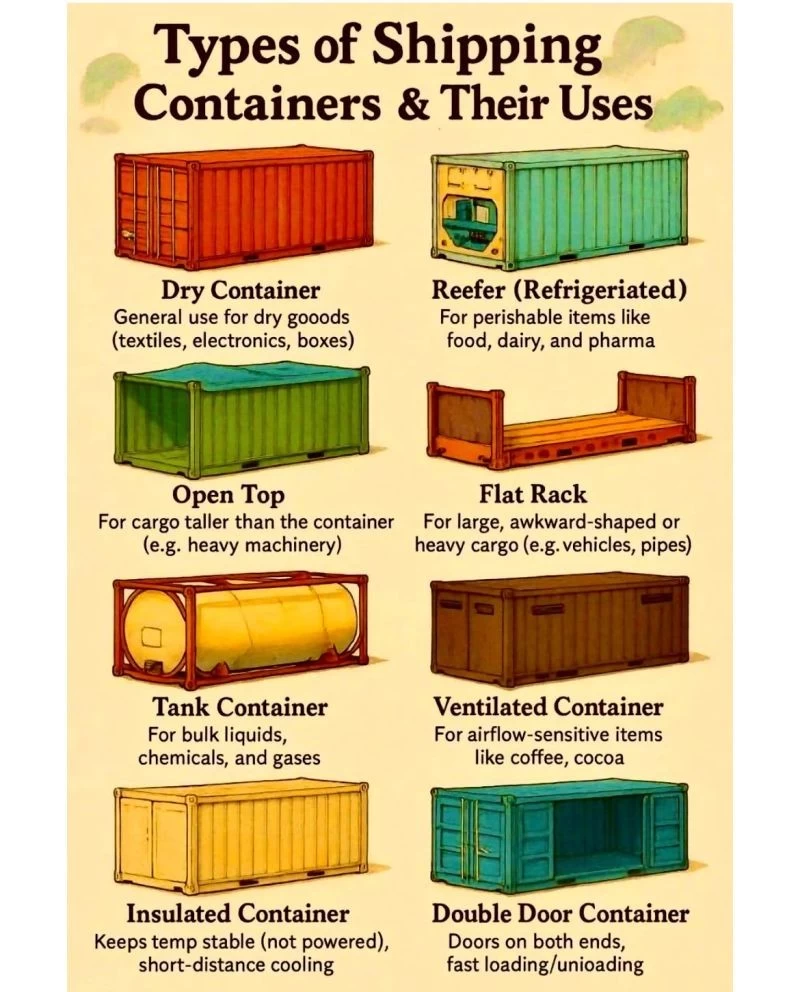

As global trade accelerates in 2025, more exporters and eCommerce brands are building independent websites to reach international customers directly. But one challenge remains universal: choosing the right shipping container type for each shipment.

Whether you are sending consumer products, machinery, fresh food, or long oversized cargo, understanding ocean freight containers can significantly reduce logistics costs, prevent cargo damage, and improve transit efficiency.

This article explains all major shipping container types, including GP, High Cube, Double Door, Open Top, Flat Rack, Reefer, and more—using simple language tailored for shippers and logistics teams who need practical guidance for real-world shipping decisions.

Below is a complete breakdown of the container types most frequently used in global ocean freight shipping. Understanding these options will help you make informed decisions that protect your cargo and optimize shipping costs.

Modern shipping containers are designed for specific cargo requirements. Selecting the appropriate container type can mean the difference between successful delivery and costly damage claims.

| Container Type | Abbreviation | Best For | Key Feature |

|---|---|---|---|

| General Purpose | GP / DRY | General cargo, boxes, pallets | Most economical |

| High Cube | HC / HQ | Bulky lightweight cargo | 1 foot extra height |

| Double Door | DD | Long cargo, steel pipes | Front and rear doors |

| Open Top | OT | Over-height cargo, machinery | Removable roof |

| Flat Rack | FR / FK | Oversized equipment, vehicles | Open sides |

| Platform | PL | Ultra-heavy project cargo | Flat platform only |

| Reefer | RF / RE | Frozen food, pharmaceuticals | Temperature controlled |

| Ventilated | VENT | Coffee, cocoa, agricultural | Airflow system |

| Flexitank | FLEXI | Bulk liquids, oils, juices | GP with flexible bag |

Understanding container specifications is crucial for accurate freight calculations and cargo planning. Below is a comprehensive comparison of key parameters for the most common container types.

| Container Type | Size | Internal Dimensions (L×W×H) | Capacity (CBM) | Max Payload | Tare Weight |

|---|---|---|---|---|---|

| GP Container | 20ft | 5.90m × 2.35m × 2.39m | 33 CBM | 28,200 kg | 2,300 kg |

| GP Container | 40ft | 12.03m × 2.35m × 2.39m | 67 CBM | 26,700 kg | 3,800 kg |

| High Cube (HC) | 40ft | 12.03m × 2.35m × 2.70m | 76 CBM | 26,580 kg | 3,920 kg |

| High Cube (HC) | 45ft | 13.56m × 2.35m × 2.70m | 86 CBM | 27,700 kg | 4,800 kg |

| Reefer Container | 20ft | 5.44m × 2.29m × 2.27m | 28 CBM | 27,700 kg | 3,080 kg |

| Reefer Container | 40ft | 11.58m × 2.29m × 2.27m | 60 CBM | 27,300 kg | 4,800 kg |

| Open Top (OT) | 20ft | 5.89m × 2.34m × 2.35m | 32 CBM | 28,200 kg | 2,360 kg |

| Open Top (OT) | 40ft | 12.01m × 2.34m × 2.35m | 66 CBM | 26,700 kg | 3,940 kg |

| Flat Rack (FR) | 20ft | 5.94m × 2.35m × 2.35m | N/A | 28,000 kg | 2,650 kg |

| Flat Rack (FR) | 40ft | 12.13m × 2.40m × 2.13m | N/A | 40,000 kg | 5,000 kg |

Key Feature: Doors at both ends

Capacity: Same as GP (33/67 CBM)

Premium: 15-20% over standard GP

Best For: Long cargo 6m+

Range: -30°C to +30°C

Power: Requires electrical connection

Premium: 2-3x standard GP rate

Best For: Food, pharma, chemicals

Liquid Capacity: 16,000 - 24,000 liters

Base: Standard 20ft GP container

Cost: 50-70% cheaper than ISO tank

Best For: Non-hazardous liquids

The General Purpose container is the workhorse of international shipping, accounting for approximately 95 percent of all container shipments worldwide.

Specifications:

Best For:

Why Shippers Choose GP: Most economical option for standard cargo, available at virtually every port worldwide, fastest booking and lowest freight rates.

High Cube containers offer 1 foot of extra height compared to standard GP containers, providing approximately 10 percent more cargo volume—critical for lightweight but bulky shipments.

Specifications:

Best For:

Cost Benefit: While slightly more expensive than GP containers (typically 10-15 percent premium), High Cube containers can reduce total shipping costs by fitting more cargo per container, potentially eliminating the need for additional shipments.

Double Door containers feature doors on both ends, solving a critical challenge for shippers of long cargo: safe loading and unloading without damage.

Specifications:

Perfect For:

Damage Prevention: Double doors eliminate the need to angle long cargo through a single opening, significantly reducing the risk of scratches, dents, and structural damage during loading operations.

Open Top containers feature a removable tarpaulin roof instead of a solid top, enabling crane loading for over-height cargo that cannot fit through standard container doors.

Ideal Applications:

Flat Rack containers have collapsible or no side walls, making them essential for oversized, overweight, or irregularly shaped cargo that cannot fit in standard containers.

Commonly Used For:

Reefer Containers are designed for cargo that must be transported under temperature-controlled conditions, making them essential for food, pharmaceuticals, and chemical industries. Equipped with built-in cooling units, reefer containers maintain stable temperatures throughout the entire shipping journey, whether by sea, land, or multimodal transport.

Available in 20ft and 40ft sizes

Temperature range: -30°C to +30°C (varies by model)

Built-in refrigeration and insulation system

Airflow management for cold-chain stability

Cargo capacity: 20ft RF (26–28 CBM), 40ft RF (55–60 CBM)

Power supply required during storage and transit (port & vessel)

Frozen food: meat, seafood, poultry

Fresh produce: fruits, vegetables, dairy

Pharmaceuticals and medical supplies

Temperature-sensitive chemicals

Any cargo requiring stable, controlled temperatures

Refrigerated containers ensure precise temperature control, preserving product quality throughout the supply chain. They are crucial for global cold-chain logistics and offer reliability, consistent airflow, and compliance with food/pharma standards (HACCP, GDP, FDA, etc.).

Ventilated Containers provide natural or mechanical airflow to prevent condensation inside the container—making them the preferred choice for moisture-sensitive agricultural products. These containers are equipped with ventilation openings along the top and bottom rails.

Available in 20ft and occasionally 40ft

Natural or forced ventilation systems

Standard 8 ft 6 in height

Cargo capacity similar to GP containers

Prevents humidity buildup and mildew

Coffee beans

Cocoa beans

Tea leaves

Spices, nuts, and dried agricultural products

Any cargo requiring moisture control and airflow

Ventilated containers reduce the risk of mold, fermentation, and humidity damage during long voyages—especially critical for tropical agricultural exports. They are widely used in South America, Africa, and Southeast Asia for commodity shipments.

A Flexitank Container is a standard 20ft GP container fitted with a flexible, disposable liquid bladder (flexitank), transforming it into a cost-efficient solution for bulk liquid transportation. Flexitanks provide up to 24,000 liters of liquid capacity, replacing the need for drums and IBC totes.

Installed inside 20ft GP containers

Liquid capacity: 16,000–24,000 liters

Single-use, food-grade or chemical-grade options

Multi-layer polyethylene construction

Suitable for non-hazardous liquids

Requires professional installation to avoid damage

Edible oils (palm oil, olive oil, soybean oil)

Food liquids: juice, wine, syrup

Non-hazardous chemicals

Industrial liquids: lubricants, additives

Any bulk liquid requiring low-cost transport

Flexitanks can reduce costs by 30–40% compared to drums or ISO tanks. They maximize capacity, reduce labor in filling/emptying, eliminate container cleaning fees, and minimize contamination risk thanks to single-use liners.

Head OfficeShenzhen, China 1,800 sqm Facility |

24/7 Available |

Phone/whatsapp+86 185-7669-5636 +86 173-1801-4877 |

Websiteswww.air-shipment.com www.fba-shipping.com |

|

27+

Years Experience

|

100%

DG Certified

|

100+

Countries

|

24/7

Support

|

Tel:18576695636

Facebook:https://www.facebook.com/profile.php?id=61551131221180

Contact Person:Anne

PDF Show:PDF

Highly customized tea processing machine to meet your special needs, strictly product quality control is our requirement .