I am a procurement manager at an import-export trading company. This story began with what seemed like a routine shipping request, but it ultimately became my deepest understanding of the international logistics industry.

It was an ordinary workday. We needed to ship a batch of reefer containers from Qingdao Port to Los Angeles, USA – three 20-foot reefer containers and one 40-foot reefer container. It sounded as normal as it could be. I didn't even realize at the time that this would become a "problem."

But when I provided the logistics department with the detailed dimensions of the containers, the issue began to surface:

These reefer containers were 0.61 meters wider than standard reefer containers.

My initial reaction was: "What's the problem with 0.61 meters?"

I soon found out.

I contacted three major domestic logistics companies in succession. Their responses were almost identical, with a tone of "professional" helplessness:

"This size is too special, beyond our standard operating range. We cannot guarantee that the port's loading and unloading equipment can match it, nor can we predict whether the weighing inspection will pass. We suggest you consider dispersed shipping or wait for a more suitable solution."

When I heard these responses, I panicked inside. This wasn't just a logistics problem; it involved project timelines, budget costs, and even customer relationships – major issues. I began searching online for "ultra-wide reefer container shipping" and "non-standard container logistics." The results were even more disappointing – it seemed the entire industry treated such "non-standard" cargo as a "hassle."

The Turning Point: An Unexpected Phone Call

Just when I was about to give up, a friend recommended Sunny Worldwide Logistics.

To be honest, I didn't have high expectations for this recommendation. After all, three professional logistics companies said "unable to solve," so how could I believe a company that might be smaller than them could do it?

But I still dialed Sunny's number.

The person who answered was Zhang, Sunny's project manager. I described my needs and the dilemma I was facing in detail. To my surprise, he didn't immediately give me a "standard answer." Instead, he listened carefully to my entire situation, then asked a series of very professional questions:

"Which terminal in Qingdao is your cargo at?" "What products are packed in these reefer containers?" "What's the approximate weight distribution of the cargo?" "What are your timeline requirements?"

These questions made me feel that he was genuinely thinking about this problem, not looking for reasons to refuse.

Finally, Zhang said something I still remember: "This is not impossible; this is our opportunity to demonstrate our professional capabilities. We'll take this project."

At that moment, I felt like I had seen a light.

After the project officially started, I truly experienced why Sunny could say such words.

Zhang arranged a detailed project kickoff meeting for me. The attendees weren't just salespeople, but also Sunny's Port Coordination Department Manager, Logistics Engineer, and Quality Control Specialist. This lineup surprised me – usually, only major projects would require such a "full deployment," and in many logistics companies' eyes, my project was a "hassle."

At the meeting, the logistics engineer gave me a detailed explanation of the two core challenges that the ultra-wide reefer container would face during transportation. After hearing his explanation, I finally understood why other companies had rejected my order.

The logistics engineer drew a simple diagram on the whiteboard and explained:

"Standard reefer container width is 2.438 meters. Your ultra-wide reefer container is 3.048 meters. Although it's only 0.61 meters different, this difference means that the port's standard gantry cranes and forklifts cannot precisely load and unload containers of this size according to existing operating procedures."

I asked: "Can't you just use different equipment?"

The engineer shook his head: "It's not that there's no other equipment available. The problem is that most logistics companies simply don't have the ability to 'coordinate' with the port to change standard procedures. The port processes thousands of containers daily and has established operating standards. Once you request 'special handling,' it means you need sufficient influence and long-term cooperation to make the port willing to allocate special loading and unloading resources for you."

He paused and then said: "This is exactly where Sunny's advantage lies. We've been cooperating with Qingdao Port and Shanghai Port for 27 years. The port trusts us. When we make a reasonable special request for a client, the port is willing to cooperate."

Hearing this, I suddenly understood – why other companies rejected me while Sunny accepted me. It wasn't just a technical problem; it was a matter of resource integration and relationship accumulation.

Sunny's port coordination staff subsequently showed me their portfolio of cooperation cases with Qingdao Port. Among these cases were many successful shipping examples of "non-standard" cargo.

I saw their name appear in numerous port operating records. This gave me confidence.

Second Major Challenge: The "Black Box" of Weighing and Shipping Compliance

Next, the quality control specialist explained the second challenge: weighing and compliance.

"Even if the port successfully loads and unloads your ultra-wide reefer container, there's still the shipping company's inspection to face. The shipping companies have strict standards – the container's weight and center of gravity must be within allowable ranges. Although ultra-wide reefer containers have greater capacity, this means the cargo distribution will be completely different, and the center of gravity position might deviate from standard parameters."

"What if the center of gravity position doesn't meet the shipping company's requirements?" I asked.

"Then it cannot be loaded onto the ship. The shipping company will request readjustment or re-weighing, which will delay your delivery. In the worst case, it could be rejected."

My heart sank again. This meant that even if port loading succeeded, I still had to get past the shipping company.

But the quality control specialist continued: "This is a problem most logistics companies cannot solve independently. They usually just passively wait for the shipping company's inspection results. But Sunny is different – we've established our own high-precision measurement system and a compliance database with all major shipping companies. We take the initiative to solve these problems before loading onto the ship."

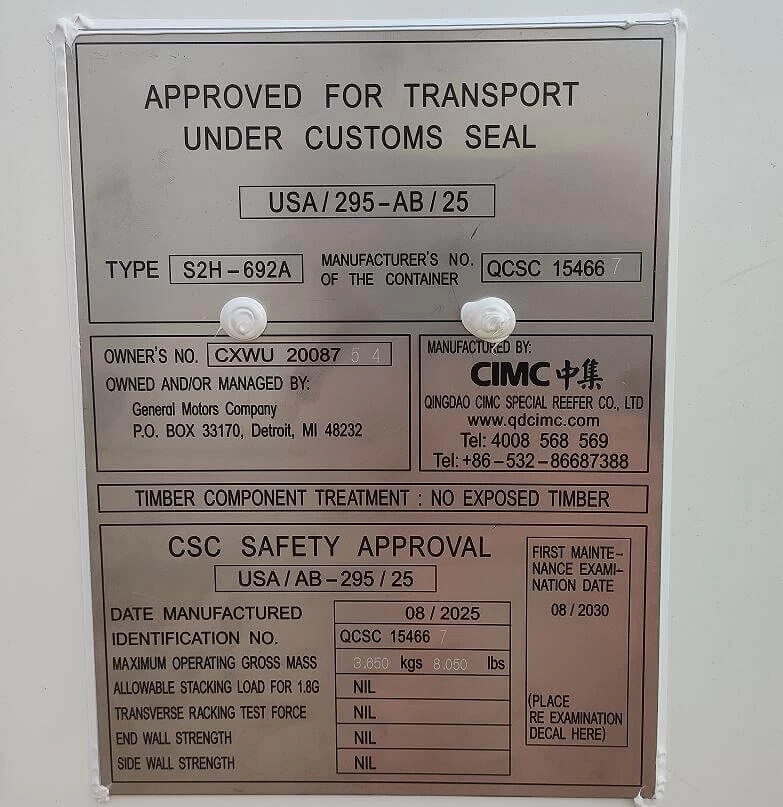

He showed me the CSC (Container Safety Convention) certification documents for the containers.

This statement completely restored my confidence. I realized that Sunny doesn't just passively execute shipping; they proactively manage risks.

After the project officially started, I began regular communication with Sunny's team about progress. During this process, I witnessed firsthand how they solved those two major challenges step by step.

Step One: The "Customized Solution" for Port Loading

A week before the cargo arrived at Qingdao Port, Sunny's port coordination staff had already begun contacting the loading company. He showed me the email exchanges between Sunny and the port authority.

In these emails, Sunny's coordinator didn't simply say "I have an ultra-wide reefer container that needs loading." Instead, they provided detailed technical data:

This professional "proposal" was recognized and approved by the port loading company. They agreed to allocate special gantry cranes and a professional loading team to operate for Sunny.

Sunny's logistics engineer also personally conducted an on-site survey of the port. He measured the gantry crane's operating range, the actual width of the dock work area, and the warehouse door width constraints. Based on these field data, he developed a very detailed loading procedure – using multiple towing vehicles in coordination and a "segmented" loading method to ensure my ultra-wide containers could safely pass through every "threshold."

Finally, Sunny also prepared a "contingency plan" for me. Although I felt it was somewhat "over-prepared" at the time, this "preparedness" attitude definitely made me feel very secure throughout the entire process.

When loading day arrived, everything went very smoothly. Although the loading time increased by about 30% compared to standard reefer containers, the entire process had no cargo damage, equipment collision, or any time delays.

Step Two: "Proactive Control" of Weighing and Compliance

After loading was complete, I thought the job was done. But Sunny's quality control specialist told me that the most critical step was still ahead – weighing and shipping company inspection.

Sunny established a set of high-precision electronic weighing platforms at the port. Unlike ordinary scales, this system adopted a "four-point support" professional design, capable of simultaneously measuring the pressure values at all four corners of the container. This allows for precise calculation of the cargo's center of gravity coordinates, with accuracy reaching ±0.05 meters.

When the weighing data came back, Sunny's engineer immediately compared it with their internally maintained maritime compliance database. This database stores all compliance parameters for all major shipping companies.

Through this analysis, Sunny discovered that the cargo center of gravity position for one 20-foot reefer container and the 40-foot reefer container slightly exceeded the shipping company's standard parameter range.

I was a bit nervous at the time – "Does this mean the cargo needs to be reloaded?"

But Sunny's team remained calm. They immediately took action: On one hand, the loading team quickly adjusted the cargo stacking position in these two containers, "fine-tuning" the center of gravity to within acceptable range. On the other hand, Sunny proactively contacted the shipping companies, submitting detailed technical reports, including the container's specific dimensions, precise center of gravity coordinates, loading recommendations, and Sunny's quality assurance statement.

This proactive approach completely changed my understanding of what a "logistics company" should be. Most logistics companies might just passively wait for the shipping company's inspection results. But Sunny is different – they proactively communicate with shipping companies, actively provide data support, and actively offer guarantees.

Finally, all containers passed the shipping company's weight and center of gravity inspection on the first try. No delays, no special requests.

Shipment Tracking and Successful Delivery

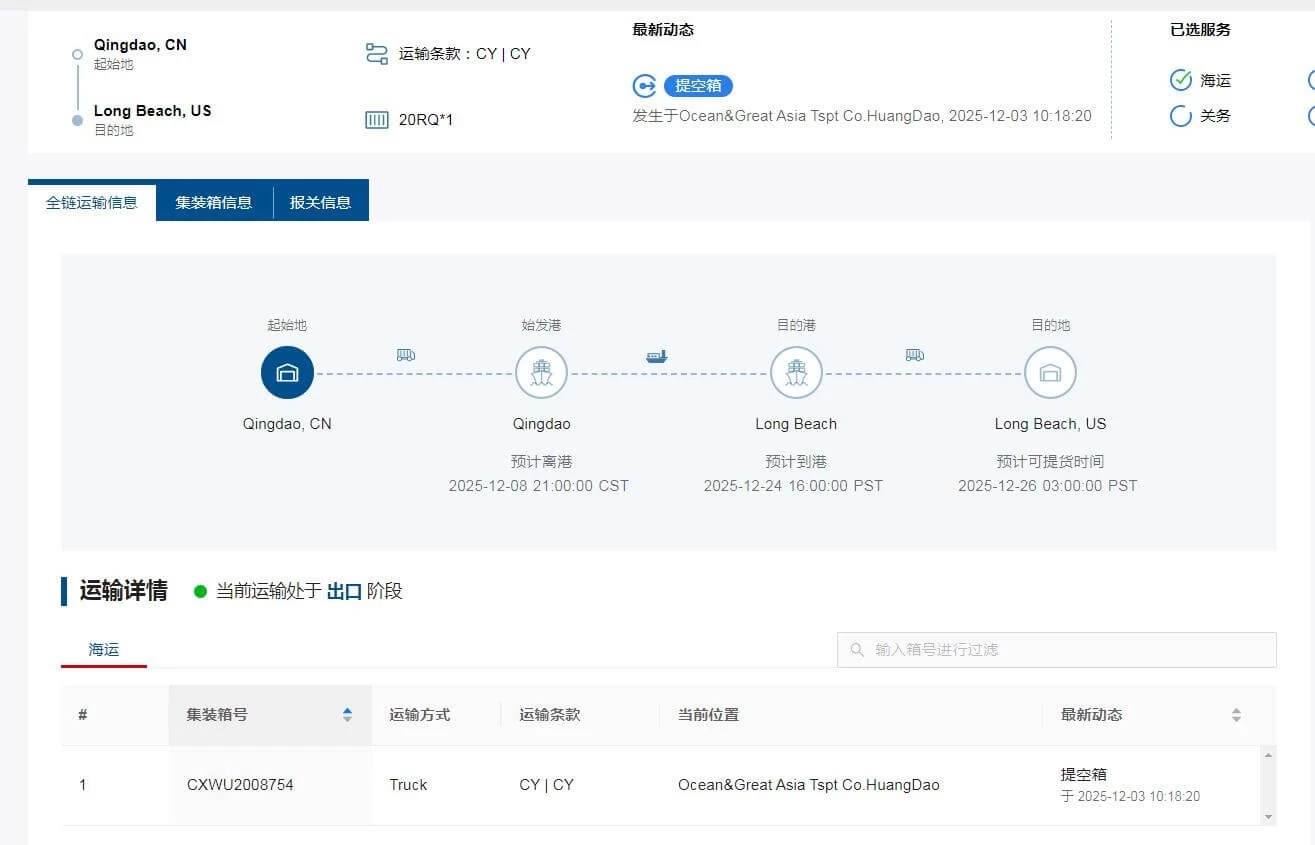

Throughout the entire shipping process, I could monitor the containers' progress in real-time through Sunny's tracking system.

The containers were successfully loaded onto the vessel and departed from Qingdao on December 8, 2025, with an estimated arrival in Long Beach on December 26, 2025. Every step of the journey was transparent and on schedule.

The entire process – from initial contact to final delivery – demonstrated Sunny's commitment to excellence and their ability to handle what other companies considered "impossible."

The entire project cycle took about 3 weeks, from first contact with Sunny to successful shipment. During these 3 weeks, I experienced the journey from "consecutive rejections" to "perfect resolution."

Looking back now, I've learned several lessons:

First, "impossible" often stems from lack of capability, not from true impossibility. When the other three logistics companies said "unable to solve," it wasn't because the matter was truly unsolvable, but because they lacked the resources, experience, and professional capability needed to solve it. Sunny could take on this project precisely because they had these things.

Second, professionalism is reflected not only in technology but also in relationships and accumulated experience. Sunny has 27 years of cooperation history with ports, which gave them the authority to "change port standard procedures." Most logistics companies don't have such accumulated relationships, so they can only passively follow established rules.

Third, true service means proactively foreseeing risks rather than passively enduring them. From identifying the two major challenges at the kickoff meeting, to on-site surveys of port loading, to post-weighing adjustments and communication with shipping companies, Sunny's entire approach reflected the philosophy of "proactive risk management." This made me feel secure throughout the process, not anxious.

Finally, I realized an important fact that many people overlook – there are many cheap logistics companies, but truly professional ones are rare. In this project, I didn't pay excessive fees for "special handling of ultra-wide reefer containers." Sunny's pricing was actually very competitive. But the value they provided far exceeded the price itself.

After this cooperation, we established a long-term partnership with Sunny. We've now handed other "problematic" projects to them as well – such as oversized machinery equipment, cold chain food, special hazardous materials, and so on. Every time, Sunny has exceeded our expectations.

I've even recommended Sunny to my colleagues. Whenever they complain about certain "special cargo that cannot be shipped," I tell them: "Contact Sunny Worldwide Logistics. They'll tell you that there are no unsolvable shipping problems, only solutions that haven't been found yet."

Dear Sunny Worldwide Logistics Team,

Thank you for your professionalism, patience, and innovation throughout this project. You not only completed a cargo shipment but also changed my understanding of the international logistics industry.

In you, I see what "27 years of accumulation" means, what "customer-centric" truly looks like, and what "professional spirit" really is.

I've decided that all of our company's international logistics needs going forward will prioritize Sunny. Because I know that no matter how complex or "special" the requirements, you can use professionalism and experience to turn the impossible into possible.

Thank you for your continued trust and support!

– Procurement Manager, Import-Export Trading Company

Thank you to this client for their trust and for sharing their story. Our original mission is to solve the most challenging logistics problems for every client. This ultra-wide reefer container project is the perfect embodiment of that mission.

In the international logistics industry, we uphold one belief: There are no "impossible shipments," only "solutions that haven't been found yet."

If you also have special cargo shipping needs, please contact Sunny. We're ready to use 27 years of professional experience and innovative capability to develop the optimal customized solution for every shipment.

Sunny Worldwide Logistics

Your Trusted Global Logistics Partner Since 1998